HEMC High Performance Cellulose Ether untuk Lem Keping, Mortar, dan Plester

Meeting the Demands of Next-Generation Building Materials

In today's fast-paced construction environment, the expectation for building materials has evolved far beyond traditional standards. Contractors, manufacturers, and developers alike are demanding products that deliver not only strength and durability but also enhanced workability, improved performance under diverse climate conditions, and compliance with increasingly strict environmental regulations.

Landercoll® Hydroxyethyl Methyl Cellulose (HEMC/MHEC) was engineered to answer these demands. When integrated into construction products, Landercoll® HEMC transforms performance — extending open time, increasing water retention, and enhancing bonding strength — all critical parameters for professionals who refuse to compromise on quality.

Premium HEMC Product

High-performance cellulose ether for construction

Understanding Hydroxyethyl Methyl Cellulose (HEMC/MHEC)

Hydroxyethyl Methyl Cellulose is a non-ionic cellulose ether derived from refined cotton and wood pulp. The hydroxyethyl and methyl groups introduced during etherification create a polymer that interacts predictably with water, cement, gypsum, and other binder systems. As a non-ionic polymer, Landercoll® HEMC is chemically stable across a wide pH range, making it suitable for various construction applications without risk of premature degradation.

Key Advantages for Construction Applications

Superior Water Retention

Molecular structure slows water evaporation, maintaining optimal hydration for cement and gypsum systems, preventing premature drying.

Enhanced Workability

Modifies viscosity and thixotropic behavior, allowing for smoother troweling, easier spreading, and consistent layer formation.

Extended Open Time

Longer open time enables workers to adjust tiles or smooth surfaces without rushing, reducing error rates and material wastage.

Improved Bonding Strength

Better hydration and adhesion promotion result in finished surfaces with superior tensile and shear strength performance.

Eco-Friendly & Safe

Odorless and non-toxic, supporting healthier working conditions and reducing environmental impact through renewable materials.

Technical Specifications – Precision You Can Rely On

Available Grades: Standard, Modified, and Pure Grades for precise formulation tuning.

Supply: MOQ 1000 kg, shipping from Shandong, China with 7-14 day lead times.

Advanced Laboratory Testing & Quality Assurance

Our state-of-the-art application test center ensures every batch of Landercoll® HEMC meets the highest standards through comprehensive testing protocols. Independent lab testing demonstrates superior performance in real-world construction applications, providing manufacturers with confidence in product consistency and reliability.

Open Time Testing

Rigorous tile adhesive open time experiments validate 25% performance improvement

Bond Strength Analysis

Comprehensive testing confirms 15% stronger bonding compared to generic grades

Batch Consistency

Every production lot undergoes viscosity, content, and performance verification

Typical Applications in Modern Construction

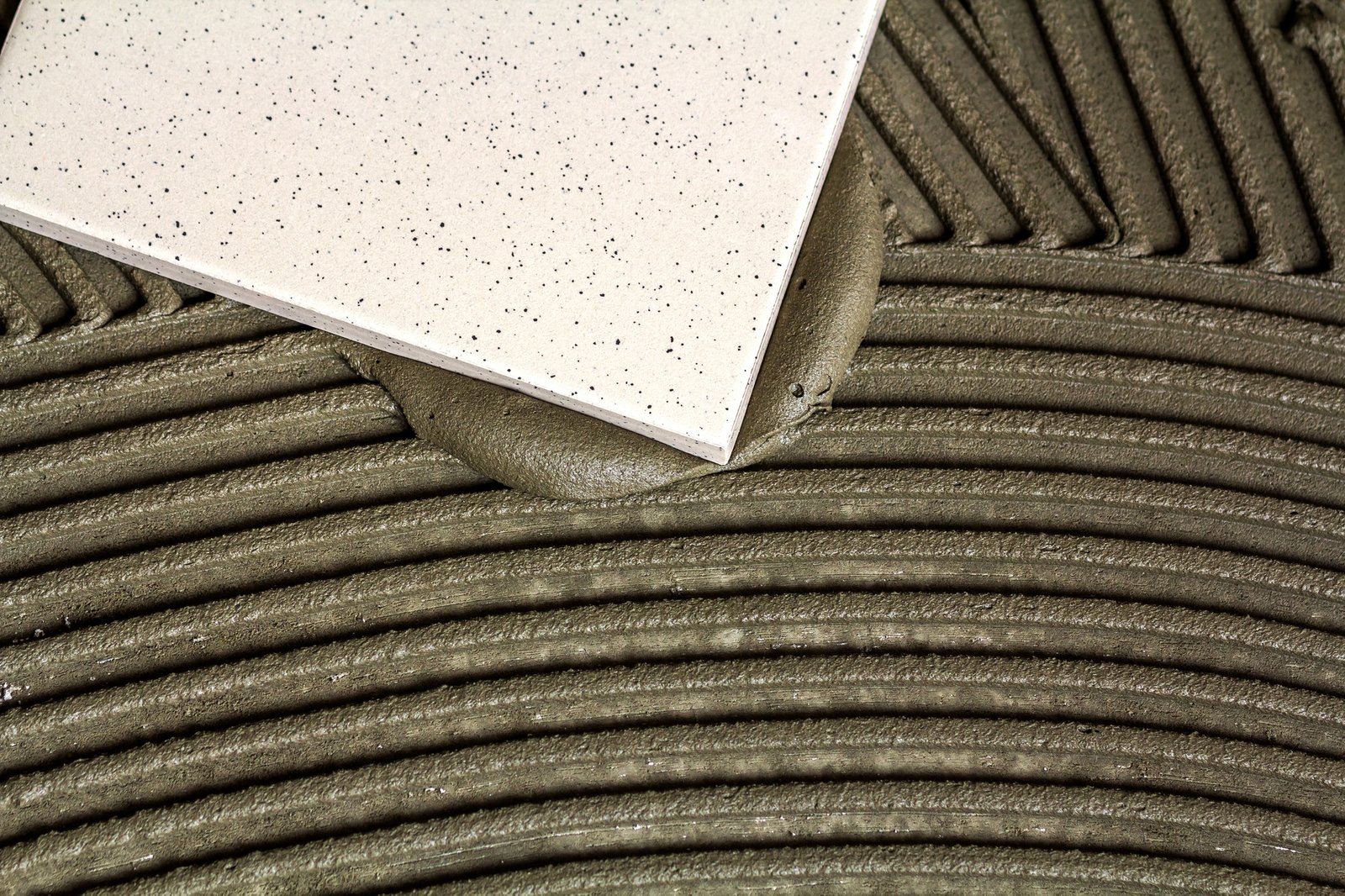

Tile Adhesives

In high-performance ceramic and porcelain tile installations, precise rheology and strong adhesion are non-negotiable. Landercoll® optimizes these parameters, helping adhesives meet EN 12004 standards.

- Meets EN 12004 standards

- Precise rheology control

- Superior ceramic bonding

Gypsum-Based Plasters

Improved open time and water retention make application easier and surfaces more resilient, with enhanced workability for fine decorative finishes.

- Extended open time

- Superior water retention

- Enhanced resilience

Dry-Mix Mortars

Whether for masonry, plastering, or repair, Landercoll® enhances cohesiveness, water demand control, and frost resistance for consistent performance.

- Enhanced cohesiveness

- Water demand control

- Improved frost resistance

Wall Putty & Skim Coats

Formulations gain improved smoothness, minimal shrinkage, and excellent coverage, critical for achieving fine decorative finishes. Also suitable for joint fillers, self-leveling compounds, and EIFS systems.

- Smooth finish quality

- Minimal shrinkage

- Excellent coverage

Manufacturing Process and Quality Control

Producing world-class HEMC involves stringent raw material selection, precision etherification, and thorough purification. Landercoll®'s process ensures reproducible degrees of substitution and viscosity through proprietary reaction conditions, advanced drying systems for particle uniformity, and comprehensive quality testing.

Input Purity Control

Multiple washing and refining stages for raw materials

Controlled Etherification

Proprietary reaction conditions for consistency

Advanced Drying & Milling

Maintaining particle uniformity throughout

Final Quality Check

Comprehensive testing for every batch

Working with Landercoll® – Formulation Tips & Performance Data

Formulation Guidelines

Comparative Performance Advantages

Compared to other cellulose ethers like Hydroxypropyl Methyl Cellulose (HPMC), Landercoll® HEMC offers distinct advantages in water retention and salt tolerance, making it particularly effective in high-alkaline cement systems and gypsum formulations.

Pertanyaan yang Sering Diajukan

Comprehensive Sample Program & Technical Documentation

Experience Landercoll® HEMC performance firsthand with our comprehensive free sample program. Each sample shipment includes detailed technical documentation, formulation guidelines, and access to our expert technical support team.

Free Sample Kits

Multiple grade samples with testing guidelines

Technical Documentation

Complete product brochures and specifications

Testing Support

Laboratory protocols and performance validation

Environmental Sustainability & Green Building Support

Landercoll® HEMC stands out not only for technical excellence but also for sustainable manufacturing practices that support modern green building initiatives and environmental compliance requirements.

Renewable Raw Materials

Reduces petrochemical reliance through cotton and wood pulp sourcing

Low-Emission Processes

Complies with environmental regulations in target markets

Sustainable Packaging

Bulk packaging minimizes waste and transport impact

Green Building Certifications

Supports LEED, BREEAM, and other sustainability standards

Why Landercoll® HEMC Is the Smarter Choice

Landercoll® Hydroxyethyl Methyl Cellulose isn't just an additive — it's a performance platform engineered to push the boundaries of what construction materials can achieve. For manufacturers and contractors aiming to meet rising technical, environmental, and regulatory standards.

Quick Reference Guide

Product Grades

- Standard Grade HEMC

- Modified Grade HEMC

- Pure Grade HEMC

Performance Benefits

- 25% greater open time

- 15% stronger bond strength

- Superior water retention

- Enhanced workability

Supply Information

- MOQ: 1000 kg minimum

- Origin: Shandong, China

- Lead time: 7-14 days

- 24+ months shelf life